|

|||||||

|

|

|||||||

|

THE ROTARY PARAGMA |

|||||||||||

|

The PRAGMA is an AVID FLYER HEAVY HAULER I built in 1999/2000 from a kit. This kit came with a ROTAX 583 snow mobile engine. I considered this engine a no-option for various reasons. In search for an engine, I came across Tracy Crook’s book about his installation of a MAZDA rotary in his RV4. It turned out very quickly that this engine is about twice too big in power and in size/weight. I joint the Rotary enthusiast community anyway. At the first gathering I attended, someone offered me a Subaru engine, which ended up in the PRAGMA. This engine served me very well with absolutely no problem during 10 years of operation. The name PRAGMA for my airplane was the result of my attitude to building the airplane. I wanted an airplane that can easily fly off my grass strip, but does not have to be exceptionally “pretty”. This pragmatic approach gave me the idea for the name. Even so the Subaru engine installation was a big effort, with redrive and motorcycle carburetors and so forth, I always considered it a temporary solution for giving me something to fly until I find a suitable rotary engine.

Conversion issues with the Subaru where no different from what a rotary installer encounters. Unless you are willing to use an overkill radiator, one has to go through the process of optimizing everything from air flow to coolant flow, and that is usually time consuming. It was for me too. It still was worth every bit of the effort.

What happened to the rotary idea? See “One Rotor Wankel”.

|

|||||||||||

|

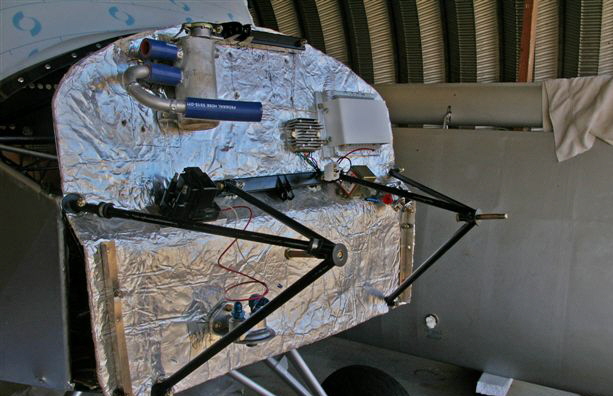

Installing the Single Rotor Wankel into the PRAGMA. Toward the end of developing the Single Rotor Wankel named “RES12”, I started getting serious about the installation. Considering an engine mount, the existing hard points were a real problem in regard to their location. One good point was, there are three hard points on each side, designed for a ROTAX 582 in a cylinder-down position. To make another long story short, I decided to add two more hard point at the lower outside corners of the fire wall. So here we go removing everything from the seats forward and start cutting and welding. This ended this ended with a new wind shield, new instrument panel and everything that goes with it.

|

|||||||||||

|

|||||||||||

|

The lower two hard points were added to the frame. |

|||||||||||

|

Finally by mid February 11, the instrument panel wiring, as the last effort on the airframe modifications was completed. The new instrument panel lay out was, at least to some extent driven by RES12 engine specifics. |

|||||||||||

|

|||||||||||