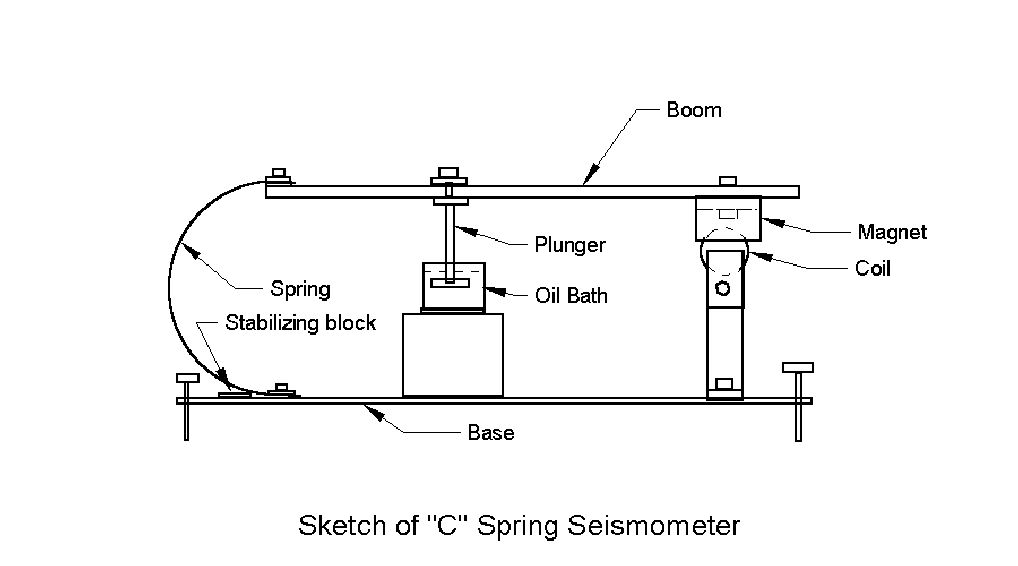

The ''C'' Spring Seismometer

A very simple but effective seismometer can be made by utilizing the spring characteristics of a hacksaw blade. The low cost and ease of construction are likely to entice many amateur seismologists into constructing an instrument based on this design once the details of construction become easily available. This web page contains the details necessary to construct a vertically polarized ''C'' Spring Seismometer.

This seismometer has all the parts common to every seismometer including damper and spring. What is unusual is the elimination of a moving hinge and associated friction and noise.

Except for the springs, the structural materials are aluminum to prevent magnetic interactions. A wood structure could also be used but would bring potential problems with moisture and swelling, creating a need to change the adjustments frequently.

Here is a brief description of components:

Frame

A single flat piece of aluminum 1/4 inch by 4 inches by 24 inches is used as the

base and frame. Three holes are drilled into the base and threaded for use as

support legs and leveling adjustment. Additional holes are drilled and threaded

for mounting the springs (hacksaw blades) and coil support.

It is important to use a non-magnetic material for the base to prevent

difficult interactions with the sensor magnet which will be mounted on the

boom.

Boom

The boom is 1/2 inch square aluminum tube 24 inches long. This also must be

non-magnetic to prevent interactions with the magnet. Two threaded holes and

one clean hole will be made in this member. The damper will be clamped to the

boom.

Springs

Two hacksaw blades are used for the springs. The blades must be sufficiently

flexible to allow bending them into a half circle. Longer springs are better so

use the longest hacksaw blade available. Band saw blades could also be used.

Used blades would work equally well as new blades. It is important to grind the

teeth from the blades to allow for a smooth bending throughout the length of

the spring. With the teeth in place, the blade has a non-uniform width which

results in a concentration of stress at the root of each tooth.

Caution! The loaded springs have considerable stored energy and could cause injury if broken or accidentally released. Stay away from the probable path of the broken or accidentally released parts.

Coil and magnet

The coil and magnet must be matched to ensure that the coil will mesh with the

magnet. A horseshoe magnet is pictured but a speaker magnet could be used with

appropriate mounting changes. The coil can be taken from a 120V-240V relay.

Most seismic amplifiers are high impedance devices so the coil should have as

many turns as possible. 120V-240V relay coils typically have more turns than

coils from automotive relays and are preferred.

Some builders prefer to place the magnet on the base and coil on the boom. This

has the advantage of reducing local magnetic disturbance of the boom, but the

disadvantage of more complex construction.

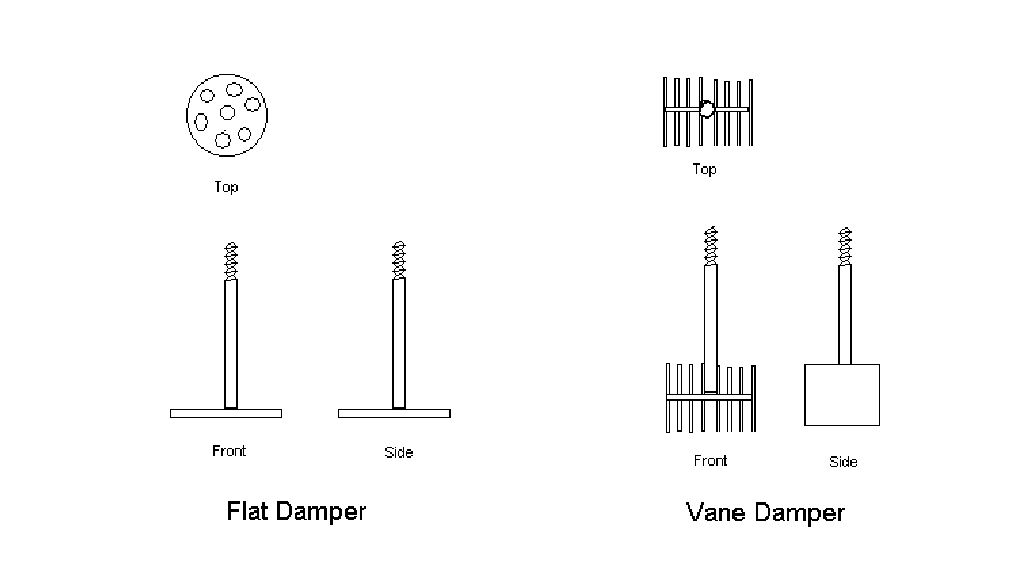

Damper

A damper is necessary to prevent energy from the first seismic wave from carrying over to later waves. A oil damper is used because of the simplicity of this method. A choice can be made between a simple flat plunger or the more complicated vane assembly. The vane damper will allow a wider frequency response which included higher frequency waves desired at this location.

The flat damper can be made from a 1 inch diameter washer. Drill holes in

the washer to improve the higher frequency response.

The vane washer can be made from thin material such as copper or a tinned

material taken from food cans. The plates can be assembled parallel by placing

removable cardboard spacers between each plate before soldering in place. A

vane 1 inch by 1 inch by 1 inch worked well for the pictured seismometer.

The viscosity of the oil is adjusted to control the damping. Underdamping allows energy from one cycle to carry over into the next cycle. Overdamping decreases the sensitivity of the instrument. Test for correct damping by displacing and then releasing the boom. The trace from a correctly damped boom will return to the zero position with a small overshoot. The pictured seismometer is slightly over damped with the trace returning with no overshoot.

Assembly

The springs made from hacksaw blades are clamped to the base and boom under

1/8 inch by 1 inch flat strips about 3 inches long. The blades are spaced 2

inches apart center to center.

The damper is clamped onto the boom to allow for easy adjustment laterally

along the boom. The damper is placed about in the middle of the boom but

placement is not critical.

The magnet is bolted as far out on the boom as possible while meeting the goal

of a horizontal boom.

Stabilizing blocks

Cut two 1/8 inch by 1 inch by 1 inch aluminum blocks. These will be used to

stabilize the boom which will be unable to find a stable position when the

springs are clamped parallel on a flat base. Stability will come when we place

these blocks on the base and under each spring so that the outside edge of each

spring is slightly higher than the inside edge. Each spring then has a 'bias'

toward the center and stability is easily achieved.

The pinching effect from the springs is enough to hold the stabilizing

blocks in place. No further attaching of the blocks to the base is needed.

Adjustment

Adjustment is easy. First, make make the coil support height correct to allow the coil to mesh with the magnet when the boom is parallel with the base. Then place the instrument on a suitable surface and adjust the base screws to make the base level.

Make very rough adjustments by sliding the magnet and damper along the boom (while the damper is NOT in the oil bath) until a horizontal beam position is obtained. Adjust the stability blocks interactively with the magnet and damper.

When a stable position is found with the boom level, add the oil bath assembly and insert the damper plunger. The boom will float higher so the damper will need to be moved further out (away from the springs) on the boom.

Final adjustment is made with the base adjusting screws. Be sure that the coil does not contact the magnet. The smallest link between the two parts, even if as small as a spider thread, will destroy the sensitivity of the instrument.

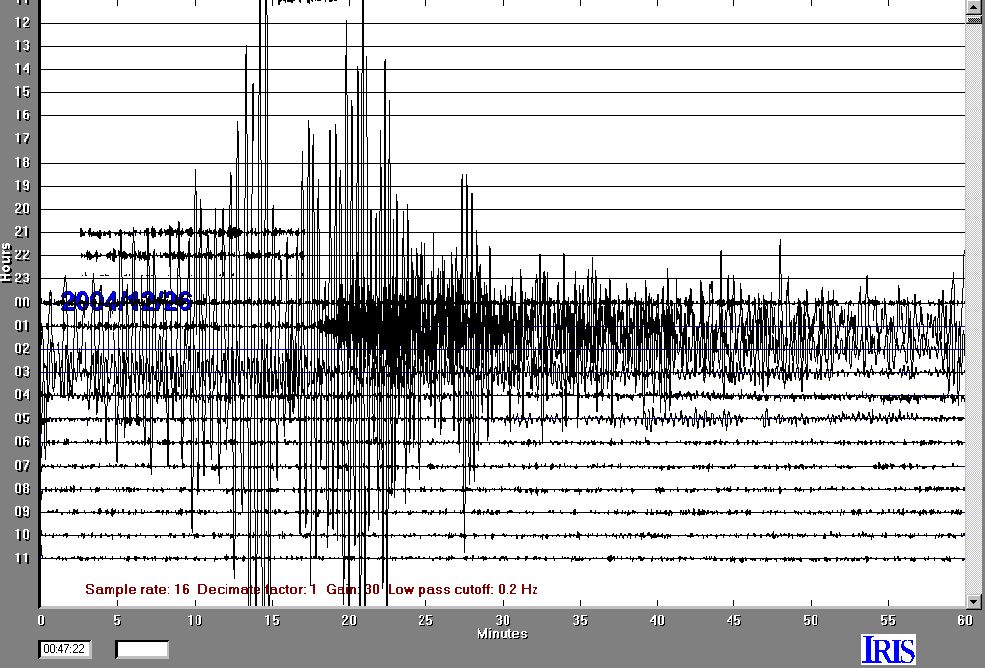

Results

The instrument is sufficiently sensitive to see small earthquakes riding on the microseims caused by ocean wave action and observable worldwide. Sensitive drops off below about 0.2 Hertz. The period of the pictured seismometer is between 5 and 6 seconds.

Long term stability is good. Expect to adjust the new instrument within a few days as all the parts settle in to a stable configuration. Once stable, the instrument will go for months without needing adjustment.

This recording of the December 26, 2004 Sumatra magnitude 9.0 quake was

detected with the instrument in the photo at the top of the page. The signal

was amplified with the Saum A/D

conversion/amplifier board and recorded with Amaseis

software.

Click here for a more printer friendly version

of this page.

September 15, 2005

rsparks@elltel.net

Febuary 6, 2021 update. Changed a few words for additional clarity. This instrument has been retired. In it's place is a seismometer using a flat spring made from a spackling knife blade. By using a flat spring (flat under load) we can use magnetic damping, allowing better frequency damping characteristics.